From Day 1, Taylor’s innovative spirit has been a driving force behind our efforts to improve the guitar-playing experience. From our ultra-playable necks to high-tech finish application, here are 10 game-changing Taylor innovations. For a longer list of 40, see our story “40 Years of Taylor Innovation” in the fall 2014 issue of our company publication, Wood&Steel.

Download Volume 80 of Wood&Steel

1. Computer-controlled Milling (1990)

Taylor was the first acoustic guitar company to use computer numerically controlled (CNC) mills. The machines brought exacting precision when it came to cutting, pocketing and shaping complex guitar components and brought unprecedented consistency to the guitar-making process. CNC mills also were used to fabricate proprietary fixtures and other tools that helped improve Taylor’s guitar-making methods. They became a key catalyst for other innovations and helped spur Taylor’s growth into an industry-leading manufacturer.

2. Grand Auditorium (1994)

The medium-size body style was the crystallization of Bob Taylor’s aesthetic design sensibility. An alternative to the traditional Dreadnought, its proprietary contours helped produce a clear and balanced tone profile and delivered a more versatile guitar that could handle a mix of flatpicking, strumming and fingerstyle playing. The guitar’s signature clarity and balance also fit into an instrument mix nicely, making it a go-to guitar for session musicians and gigging players. It became the bestselling Taylor body shape and redefined the acoustic guitar to better fit the needs of the modern player.

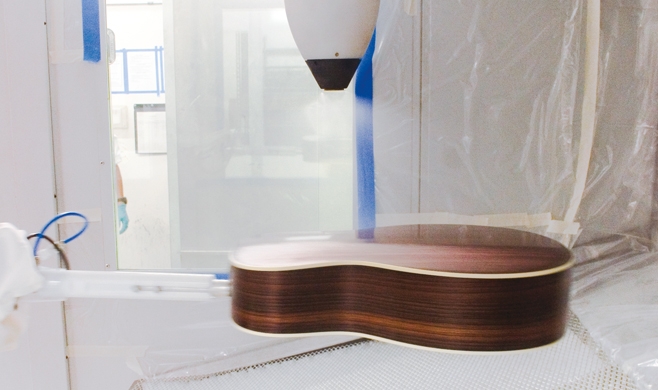

3. UV-Curable Finish (1995)

Taylor pioneered the development of new polyester-based guitar finishes that are more durable and contain fewer solvents than traditional nitrocellulose lacquer finishes, and can be applied in thinner coats to optimize the tonal properties of the guitar. Taylor’s design of an ultraviolet (UV) light curing oven enabled the curing time to be reduced from days to minutes.

4. Laser Technology (1996)

After first using lasers to etch the rosette pattern for the Baby Taylor, the company expanded their use to include the cutting of guitar tops, backs, sides, intricate inlays, and other guitar components. Controlled by computer programs, lasers are able to cut wood parts quietly, accurately, and without chipping since there are no high-speed rotating cutters to stress the material.

5. NT Neck (1999)

Taylor’s patented NT neck was arguably the first major advance in acoustic guitar design since the birth of the steel-string. The neck design utilized computer mill and laser technology to change the way Taylor’s bolt-on neck attaches to the body of the guitar. The design brought more stability and precision to the neck, enabling unprecedented micro-adjustability to ensure a precise neck angle and easy serviceability to maintain the perfect neck angle. The three-piece design also brought greater structural resilience to the neck and reduced the waste of mahogany and sapele wood.

6. Expression System® Acoustic Electronics (2003, 2014)

After years of installing after-market pickups from outside manufacturers, Taylor’s product development team applied its extensive guitar knowledge to design a proprietary pickup system capable of capturing a guitar’s rich acoustic nuances and translating them into a more natural amplified tone that was reflective of both the guitar and the player. The original Expression System (2003) incorporated a network of magnetic neck and body sensors and a preamp designed with input with revered pro audio designer Rupert Neve. The latest iteration, the Expression System 2 (2014), features the breakthrough redesign of a piezo-style pickup.

7. Electrostatic Finish Application (2005)

Taylor dramatically increased the transfer efficiency of the finish sprayed on a guitar from 15 percent when sprayed manually to about 85 percent with the integration of electrostatic and robotic technologies. The electrostatic application is enhanced within a controlled spray environment, in which the finish temperature and the humidity levels are stabilized to create optimal conditions for finish attraction. The resulting finish coating is more evenly applied and more consistent across the production line.

8. T5 (2005)

A revolutionary “electracoustic” guitar design, the hollowbody hybrid leveraged Taylor’s proprietary pickup design capabilities and bridged the acoustic and electric worlds in a truly unique and inspiring way, infusing a versatile palette of tones into one all-performance guitar. Compatible with both electric and acoustic amps and equipped with acoustic and electric pickups and five-way switching, the T5 was one of Taylor’s most successful product launches ever. The more recent T5z expanded the T5 family with a more compact body and a more electric-friendly feel.

9. GS Mini (2010)

Taylor’s next-generation version of a scaled-down guitar after the Baby Taylor was designed to create a bigger, richer guitar sound yet still retain the compact feel of a travel-friendly guitar. The guitar borrowed from Taylor’s shapely Grand Symphony body style and incorporated many of Taylor’s latest design ideas, including the patented NT neck. The design even included an easy- to-install aftermarket pickup, the ES-Go®. The guitar was an immediate success, yielding a full-size voice in a comfortably intimate package that suited both an active lifestyle and relaxed couch strumming.

10. Mahogany & Ebony Sourcing (2001, 2011)

Taylor’s commitment to conservation-minded tonewood consumption spurred our involvement in a pioneering mahogany sourcing partnership with remote forest communities in Honduras. By modifying our cutting specifications, we were able to increase the yield of usable wood for guitar necks from each mahogany log. The well-managed program has become a model of sustainable social forestry and enabled communities to improve their quality of life while properly managing the forest resources around them for the long-term future. In Cameroon, Taylor became the co-owner of an ebony mill in 2011. After learning that the major of ebony trees feature color variegation but were not used by instrument makers, Bob Taylor shared this revelation with the music community in order to promote its broader acceptance and long-term availability. Bob has used Taylor’s manufacturing expertise to upgrade the harvesting and milling efforts in Cameroon, improving working conditions for employees, introducing better tools and machines, and training employees to improve the mill’s processing capability. Ultimately, this will enable Cameroonian communities to build a better economy through responsible management of an important natural resource.