Taylor Guitars, one of the world’s premier manufacturers of acoustic and electric guitars, was among 1,200 businesses recognized by the California Integrated Waste Management Board as part of its Waste Reduction Awards Program (WRAP). Awarded in the category of “Manufacturer – Musical”, the WRAP awards acknowledge California businesses that show considerable commitment and reduction in the amount of waste produced annually, as well as recognize innovative uses for previously discarded materials, employee education and recycled product procurement.

“These businesses are aggressively tackling waste reduction through innovative business practices,” said Board Chair Margo Reid Brown. “Having exceeded our 50 percent waste diversion mandate, California is looking for resourceful approaches to divert the remaining materials going to landfills. Businesses like these, who create opportunities for waste diversion, will be at the forefront of a more sustainable California.”

Notable achievements by Taylor Guitars in 2007 include:

- 35 tons of cardboard – 95% of the company’s total volume were recycled. The other 7 tons were reused in various ways throughout the factory.

- Over 20,000 pounds of paper were recycled in 2007. Other recycled and reused materials included plastic wrap, used printer toners, electronic equipment and grass trimmings.

- All oil and coolant products used in the factory and in manufacturing were recycled.

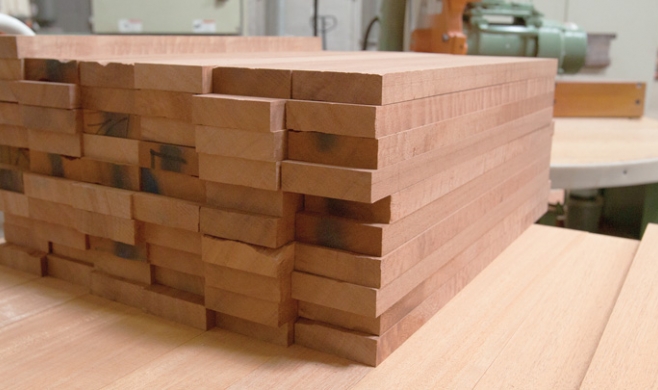

- Scrap wood and sawdust was converted into particleboard and mulch leading to its 100% reuse.

- Select pieces of scrap wood were donated to a local woodworking association to be transformed into toys for orphans in Tijuana, Mexico.

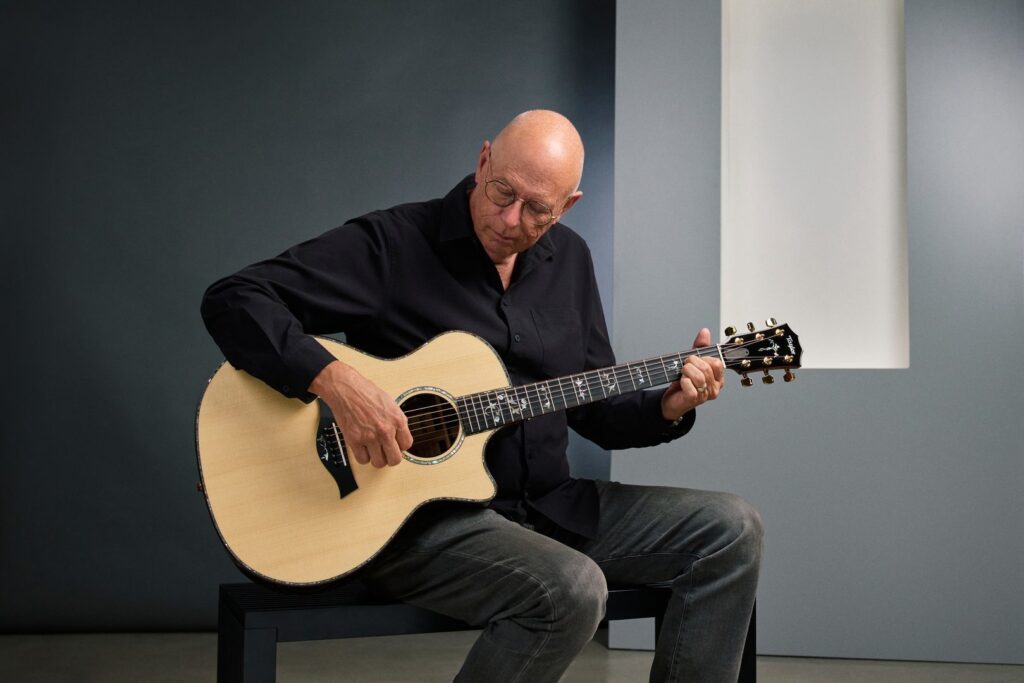

Annually, Taylor Guitars reviews its processes to look for ways to eliminate, reduce and reuse waste. One of the most notable and technologically advanced innovations was made in the early 1990s, when Bob Taylor, president and co-founder of Taylor Guitars, sought to eliminate harmful toxins from the process of spraying finish on guitars. After two years of research and development, a proprietary UV-curable finish was created. Shortly thereafter, a robotic arm was installed to hold the guitar as it passes through four coats of the UV-curable spray, eliminating all human contact in the spraying process. The guitar, which is negatively charged, creates an increased rate of transfer of spray to body, translating to less finish waste and a reduction in the levels of volatile organic compounds. For this innovation, Taylor Guitars was recognized by the County of San Diego for its commitment to the environment.

Outside of the factory, and in line with the company’s passion to produce the most aesthetically and musically pleasing guitars in the world, the company is equally committed to procuring wood that is responsibly harvested. In 2007, the company joined the Greenpeace MusicWood Coalition which is committed to FSC certification of Sitka spruce, an Alaskan forested wood that is becoming scarce due to heavy use in the construction industry.